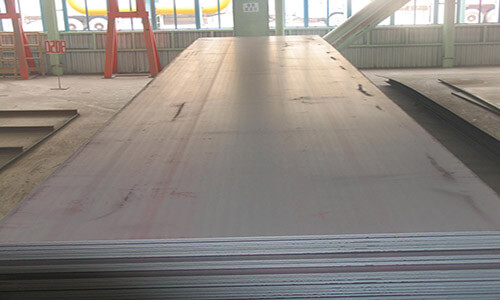

When your project requires structural steel that delivers superior strength and reliability, Quenched & Tempered S890Q Steel Plate is an ideal choice. It is engineered for extreme applications where high yield strength, toughness, and weight reduction are critical performance factors.

The S890Q grade belongs to the family of high-strength quenched and tempered steels, offering a minimum yield strength of 890 MPa. It is particularly useful in sectors such as heavy machinery, bridge construction, mobile cranes, offshore platforms, and structural components requiring enhanced load-bearing capacity. This steel is produced to comply with the EN 10025-6 standard, which ensures excellent weldability, consistent mechanical properties, and low-temperature impact resistance.

By using S890Q Steel Plate, you benefit from reduced structural weight without compromising strength, which can contribute to greater efficiency and cost savings in transportation, assembly, and long-term durability.

Many S890Q Steel Plate Importers Manufacturers focus on delivering plates with proper certification and traceability, while S890Q Steel Plate Importers Distributors play a key role in making this material available across industrial hubs. These partners help ensure you receive quality-tested steel that’s ready for use in critical applications.

The steel is also known for its adaptability in fabrication processes like cutting, bending, and welding, provided proper procedures are followed. This versatility allows engineers and fabricators to incorporate it into complex structural designs with confidence.

In conclusion, Quenched & Tempered S890Q Steel Plate is a premium-grade material that meets the challenges of high-load and high-performance structures. When sourced from reliable suppliers, it ensures strength, efficiency, and longevity for your most demanding projects.